Interlune is developing robots to harvest a valuable gas on the lunar surface that could have a big impact on Earth.

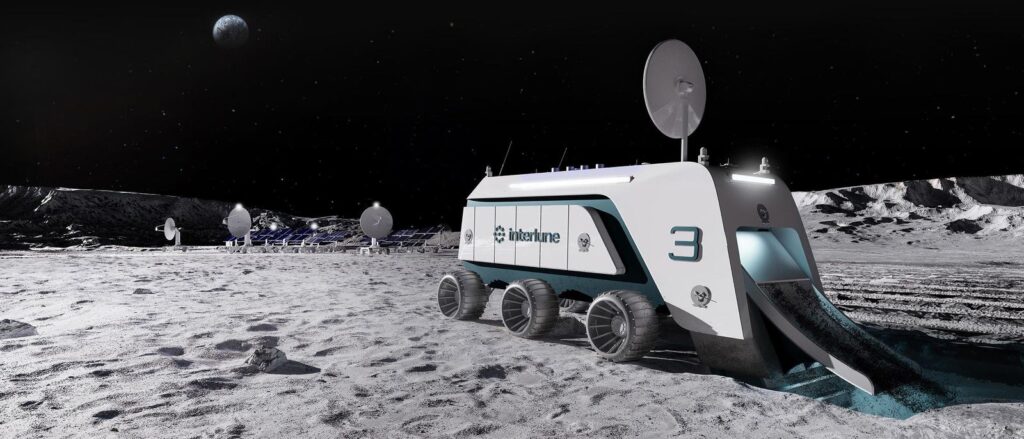

In the lobby of Interlune, a 3-foot-wide tabletop diorama shows an idyllic, toy-size version of the mining operation the Seattle startup wants to build on the moon. Boxy autonomous vehicles scrape up the top layer of lunar dirt and crush it to release gas containing a valuable form of helium. Solar panels on wheeled platforms generate power. Off to one side, a box resembling a military missile launcher is loaded with small rockets designed to carry bottles of the gas back to Earth.

What Interlune is trying to do is far from child’s play. Helium-3, an industrially prized cousin of the isotope of the gas we use to fill party balloons, is rare on Earth. In 2024 it sold for $2,500 per liter, or roughly $19 million a kilogram, according to a report from Edelgas Group. Interlune CEO Rob Meyerson expects an installation with just five of his mining machines could one day produce at least 10 kg of helium-3 a year, worth close to $200 million.

The company faces daunting hurdles to get there. Though there is more helium-3 on the moon, it’s still far from abundant. Even if Interlune can find lunar regions with higher concentrations, collecting a commercially viable amount of helium-3 means developing and transporting to the moon machines that can chew through millions of tons of regolith, the loose debris that covers the lunar surface from billions of years of micrometeorite impacts. Autonomously. With no boots on the ground to repair them as they kick up dust more abrasive than anything on Earth. “That’s one of the things we’re going to be great at,” Meyerson told Forbes.

Loud whooshes cut with a high-pitched whine from a compressor announce the presence of another thing the company needs to be great: its ultra-low-temperature distillation equipment. Interlune expects less than 1% of the gas they’ll get when they crush lunar regolith will be helium-3 – it’s estimated to exist only in the single- to double-digit parts per billion. To separate it from balloon helium and hydrogen, they’re cooling it all beyond negative 450 degrees Fahrenheit, at which point the other gases will liquefy and the helium-3 can be siphoned off.

“This is probably [our] hardest problem, but we’re making a huge amount of progress,” said Gary Lai, Interlune’s chief technical officer.

Even if Interlune is able to establish its first lunar mining camp, economic viability is still an open question, given all the unknowns as to how expensive and reliable its equipment will be, and how that intersects with the actual concentration of helium-3 in the regolith, said Chris Dreyer, a professor of space resources at the Colorado School of Mines. “I wouldn’t be surprised if they don’t make money on the first few times they do this. But over time perhaps they can.”

A bevy of startups are developing ways to exploit water and minerals on the moon to make rocket propellant or build structures there, like Starpath and iSpace. Others want to mine valuable metals on asteroids, like AstroForge, to reduce the need to dig up the Earth. But despite its many challenges, Interlune may be among those with the best shot of building a business in the near term based on bringing resources back to our planet — partly because it has ways to monetize its technology in the meantime.

Given its light weight and high value, helium-3 is widely seen as the right element to start with. Generated in the furnace of the sun, it’s deposited on the moon by solar winds that are repelled from Earth by our atmosphere and magnetic field. Scientists have figured out how to collect helium-3 produced by the decay of tritium in nuclear weapons and power plants, but that yields less than 20 kg a year.

Helium-3 is primarily used in security scanners to detect neutrons from nuclear bombs or smuggled radioactive material. Since 9/11, tens of thousands of detectors have been deployed at ports and border checkpoints.

But others are clamoring for its powerful cooling abilities. The likes of Google, Amazon and IBM are using helium-3 to bring quantum computers to temperatures near absolute zero, where they operate more efficiently.

The holy grail is to use helium-3 as a fuel to generate energy through fusion, which wouldn’t produce radiation.

Interlune has received $18 million in funding, including $15 million in a 2024 seed round led by Reddit cofounder Alexis Ohnanian’s Seven Seven Six. Partner Katelin Hollaway sees exploitation of lunar helium-3 as an inevitability and she believes Interlune’s “phenomenal” management team has the experience to execute on their gameplan. Led by Meyerson, former president of Jeff Bezos’ Blue Origin, and Lai, who ran Blue Origin’s New Shepard rocket program, the company has signed up two customers for its pilot mining attempt, which will involve sending one excavator to the moon in 2029. The Department of Energy, which manages U.S. helium-3 supplies, signed a contract this spring with Interlune for 3 liters, to be delivered at market price in 2029. And Maybell, a company making refrigeration systems for quantum computers, has agreed to buy thousands of liters over the next decade.

Interlune is going to need a lot more money to pull it off. Just how much, Meyerson won’t discuss. Dreyer, who’s working with Interlune on a NASA research contract, estimates the company will need hundreds of millions, not billions, to field one of the complete mining systems it envisions – five excavators, processing equipment, solar arrays to power them and transportation there and back.

The company plans to get some of that money from paying customers before it reaches the moon by finding terrestrial uses for its technology. Interlune is pitching companies that derive helium from natural gas to use its distillation equipment to separate the tiny amount of helium-3 also present. Meyerson thinks they could ramp to producing a kilogram a year, worth roughly $20 million.

Another near-term business: making space dirt on Earth. Interlune needs lots of simulated moon regolith implanted with gas to test its mining machines, and other companies and government agencies are eager to buy it to test their own space equipment. Interlune has won a $4.8 million grant from the Texas Space Commission to develop and mass produce regolith simulant.

Interlune’s instigator and intellectual godfather is an 89-year-old former astronaut, Harrison Schmitt, who serves as executive chairman. The only geologist to walk on the moon, as part of the last manned U.S. mission, 1972’s Apollo 17, Schmitt has advocated for lunar helium mining since the 1980s. With a team at the University of Wisconsin, he explored the potential for fusion with helium-3 and developed mining equipment concepts.

When Meyerson left Blue Origin in 2018, Schmitt convinced him to consider lunar mining. Schmitt has helped the company identify areas on the moon’s equatorial near side where they think there are concentrations of helium-3 two to three times higher than in Apollo mission samples. And he’s helped develop Interlune’s methods for harvesting helium-3.

Interlune also found an eager and well-suited partner to make its lunar excavator in Jason Andringa, CEO of Vermeer, a billion-dollar in sales manufacturer of construction, mining and agriculture equipment. Andringa, who previously worked at NASA on Mars rovers, has long harbored an interest in adapting his Iowa company’s equipment for use on the moon or the Red Planet.

Interlune is calling the machine it’s developing a harvester, because they see how it will operate as akin to a farm combine, ingesting regolith as it moves along and depositing the processed material behind it, leaving the surface looking like a tilled field. It’s designed to be the size of an electric car, and lightweight for mining equipment at just a couple of tons. Keeping it svelte is important with anything launched into space, but on the moon, where gravity is six times weaker, that poses problems. Less mass makes it harder to keep mining equipment anchored to the ground as it exerts force downward.

The equipment will have to stand up to the moon’s environmental challenges. Most of the surface is made up of a fine dust with jagged edges because it hasn’t been weathered by wind or water. On the Apollo missions, the dust eroded spacesuit boots and the seals of sample containers, and it caused sampling equipment to seize up, said Schmitt.

Add to that the stress of wide temperature swings – from 250 degrees Fahrenheit at the equator during the day to negative 410 at night – expanding and contracting metal parts.

NASA has learned how to seal mechanisms to keep dust out of rovers and landers, but that equipment hasn’t done grinding mining work. Science missions have only sampled grams of material, notes Dreyer. Interlune wants its harvester to dig up a hundred tons of regolith an hour. Vermeer and Interlune are considering ways to engineer the machines so parts that wear out can be robotically changed.

How much could the equipment cost? Meyerson says it’s premature to discuss. Dreyer estimates initial versions of the harvester could run around $20 million.

Costs could decline significantly if they manufacture at scale. “I don’t think the actual cost of the machines is going to be that substantial, in the broad scheme of things,” Andringa said. “The most substantial cost by far is going to be launching everything to the surface of the moon.”

Interlune’s development timeline is pegged to the expectation that SpaceX’s giant Starship rocket will be offering lunar service by the early 2030s, when the mining startup hopes to launch full-scale operation — a goal threatened by Starship’s recent string of test launch failures, even with last week’s success. One of the reasons Interlune believes it can prosper is the steep reduction in launch costs Starship promises. SpaceX expects the rocket to cost $100 million to start to reach low-Earth orbit, with a target of cutting the price to $20 million. And with a payload capacity of 100 tons, Starship should be able to carry all the equipment for one of Interlune’s mining camps in one or two shipments. But Meyerson said they could also use a lunar lander Blue Origin is developing, or smaller alternatives, which would entail more launches – and higher costs.

Another key question is whether their analysis is right on where to mine. Interlune is sending a spectral camera to the moon on an Astrolab rover late this year that will help confirm whether their interpretation of remote imagery of the moon’s geology is correct. In 2027, the company plans a prospecting mission to one of their target spots to analyze dirt samples.

Interlune wants to play a part beyond mining to help the U.S. erect infrastructure on the moon quickly, too. The excavation technology it’s developing with Vermeer could help build roads and trenches to install utility lines on the moon and Mars, Meyerson says. And eventually, they envision expanding to mining industrial metals, rare earth elements and ingredients for rocket propellants.

But the first step is helium-3.

Schmitt grew up helping his father, a mining geologist, prospect for copper and other metals in the Southwest. He’s excited that he might finally realize his dream of striking the mother lode on the moon. He believes it will have a big impact on Earth.

“Once there’s a reliable supply, all sorts of new things are going to be possible.”

Read the full article here